Texture Analyser & Pressure Measurements

Texture analysis

Texture analysis is the mechanical testing of food, cosmetics, pharmaceuticals, adhesives and other consumer products in order to measure their physical properties.

Because of its adaptability, texture analysis has become commonplace in many industries to measure a specific or range of characteristics or properties relating to the way a material behaves, breaks, flows, sticks, bends, etc.

Click here to see examples of typical texture and physical properties that can be measured.

Major manufacturers routinely apply texture analysis techniques both in new product development and as part of quality control in all stages of manufacture, carrying out a wide range of measurements to analyse raw materials or excipients, semi-finished goods, packaging and finished products.

It is a cost-effective method to determine the effects of raw material or excipient quality or the adjustment of formulation or processing variables on end product acceptability – whether this is to measure the ‘mouth feel’ properties of food, the flow properties of creams and pastes, the break or bend of a product or the tackiness of adhesives.

Where problematic textural issues occur during storage or transportation, texture analysis can provide a useful assessment. It may also prove to be an effective means of comparison with competitive products, or where claims substantiation is necessary to take a technical pro-active stance in your market.

Practical applications for texture analysis

It will certainly prove an indispensable tool when you need to quantify the texture or overall physical properties of your ‘gold standard’ product for future comparison in manufacture – the key to maintaining consistent textural quality!

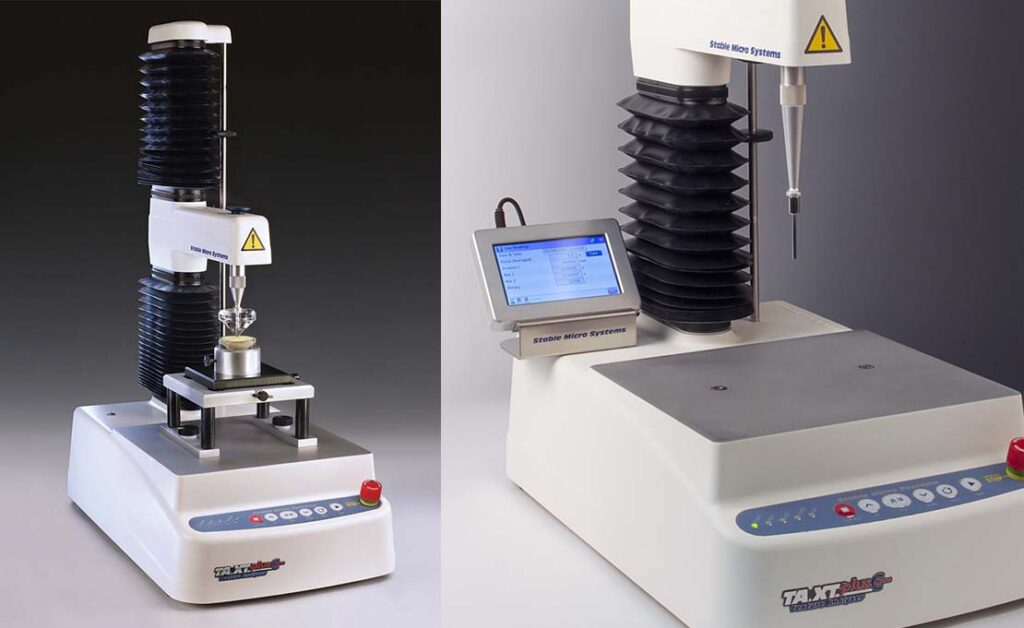

Texture Analyser

Hardness Measurement

Hardness is the measure of the mechanical resistance of a material to the penetration of another object. It can be divided into different forms depending on the type of force applied. Hardness refers not only to resistance to harder objects, but also to softer and equally hard objects. It is different from strength, which refers to a material’s ability to resist deformation and separation.

Hardness also serves as an indicator of a material’s wear behavior. For example, materials with higher hardness, such as hard eyeglass lenses and hardened gears, tend to be more resistant to scratching and wear. Hardness is critical when selecting cutting tools such as milling cutters or lathe tools, as harder cutting edges retain their sharpness longer, but can also be more susceptible to breakage.

Measuring and testing hardness is an important focus in fields such as solid-state physics, materials science, materials analysis, and geosciences to characterize rocks and minerals. Hardness is considered one of the most important material properties, along with toughness, strength, ductility, stiffness, density, and melting temperature.